The smart Trick of Abrasive Blasting That Nobody is Discussing

Wiki Article

Fascination About Dustless Blasting Near Me

Table of ContentsNot known Incorrect Statements About Sand Blasting Sand Some Known Details About Sand Blaster For Sale The Definitive Guide for Shot Blasting Near MeSome Ideas on Sandblaster For Sale You Should KnowWhat Does Sandblaster For Sale Do?Not known Facts About Pressure Washer Sandblaster

Steel nozzles will not break when dropped. Economy and also non-industrial sandblasters for house or DIY utilize usually come with low-cost steel nozzles. Based entirely on wear resistance boron carbide as well as binderless WC last up to seven-time longer than cemented WC. If you bang a boron carbide or silicon nitride nozzle right into a component, grate, or cupboard wall, after that the nozzle is more probable to crack compared to a cement tungsten carbide nozzle.The unpleasant blasting procedure removes the surface area contamination as well as converts it right into dirt. The dust and media are taken care of utilizing dirt collection agencies, commercial vacuum cleaners, as well as separators. Rough blasters can gently eliminate graffiti, paints, and also coatings without the elimination of the base product - harbor freight sand blaster. The unpleasant gun can also deeply blow up a steel surface area to totally get rid of any type of rust, scale, or followers to a NACE/SSPC "white metal" sanitation grade.

Next off, the surface is peened with small balls or microbeads to refine the surface area coating. If the part has a harsh (high roughness average, Ra) surface finish like an as-cast or as-forged surface area, then peening can modestly refine the surface area finish. If the part has actually been ground or machined to a smooth or low Ra coating, after that shot peening will certainly result in a rougher surface finish.

The Facts About Mobile Sandblasting Near Me Revealed

Finish, paints, and also adhesives stick far better to a rough surface compared to a smooth surface. An unpleasant blasted surface area produces a support profile with undercuts and more surface area for finishings and adhesives to get hold of onto. A sandblast roughened surface on a stainless hand rails helps people obtain a much better grasp also.

Corrosion as well as deterioration layers need to be eliminated too, specifically for safety finishings meeting the National Association of Deterioration Engineers (NACE) and also Culture of Surface Area Safety Finish (SSPC) criteria. 3 factors to remove corrosion or corrosion with abrasive blasting are: Corrosion and also rust layers are weak and softer compared to the underlying metal.

Not known Details About Harbor Freight Sand Blaster

A blast roughed up surface area supplies mechanical interlocking between the layer and substratum. No, since if a surface area is as well rough, after that thinner safety coatings may not fully cover the surface area causing pinholes and rust of the underlying surface. Shot, grain, and also abrasive blowing up can minimize a few of the high peaks in a surface area account to boost deterioration protective finishing efficiency.Medical/ Dental Cleaning, layer preparation, etching, and also polishing of clinical tools as well as oral remediations. For instance, the financial investment or mold and mildew material on cast crowns or bridges can be delicately removed with a small benchtop sandblaster or micro-blaster. Hip, shoulder, dental and other bone, and also joint implants are blast cleansed to satisfy strict FDA tidiness requirements.

5 to 5 microns). Certain materials such as lead-based paints and hefty metals create hazardous or toxic dust when blasted. In these applications, specialized systems are needed to avoid the release of unsafe products. Correct collection, dealing with, and disposal of the media are needed. Damp or water blasting systems lower the dirt issue.

Harbor Freight Sand Blaster Fundamentals Explained

Media as well as palatable wear components have to be gaged to preserve uniformity and afterwards fixed or changed at ideal periods to ensure top quality and security. The cost of media and also consumables need to be factored right into your sandblast cabinet choice procedure. Sandblasters or Get the facts sandblasting drivers can be wounded during unpleasant blowing up. The high-pressure rough stream can hurt skin and eyes.Soft drink, solidified carbon dioxide, and damp blowing up keep components great throughout blasting. Abrasives and also blast media can get lodged into gaps on a component and can be hard to remove. VII. Picking and Getting Sandblast Closet Begin with the size, form, and yearly manufacturing quantities grit blasting near me when taking into consideration the kind of blowing up equipment to pick.

Confirm the blasting procedure parameters with an additional examination or test. Price quote the annual operating as well as palatable prices such as pressed air, water, and electrical power intake. What are the consumable expenses such as blast media, wear part substitutes, and also system upkeep prices? What are the labor prices and training needs? Just how lots of operators are called for to run the blast system? Is special safety and also automation system training required? Send a quote for the sandblast closets together with any kind of added inquiries to make clear training along with yearly estimated operating, upkeep, and also palatable costs.

The Main Principles Of Shot Blasting Near Me

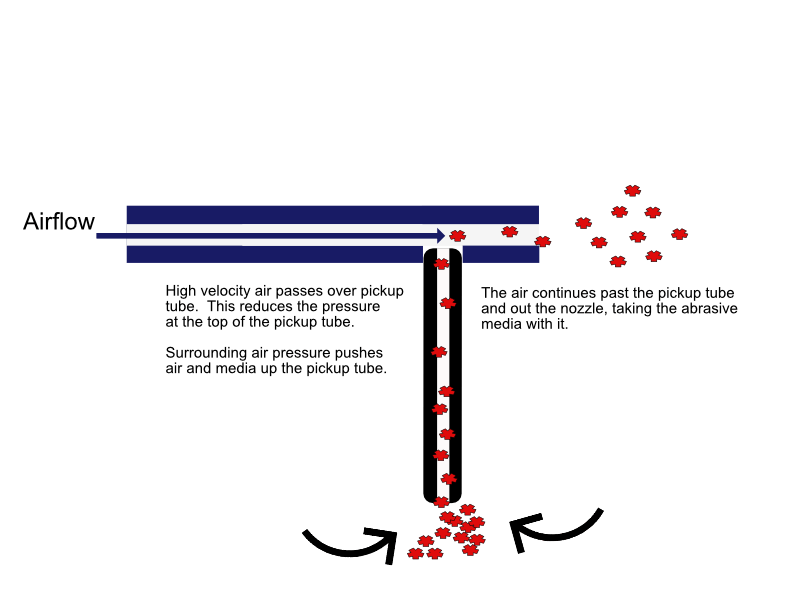

The initial of the 3 sorts of sandblaster is the gravity-fed design. There are 3 basic parts to this design: an air compressor or pressurized air tank, a hand-held stress gun with airline and a hopper on top of the gun. The tube attaches to the air container, and also the hopper is loaded with silica sand.

They include a large container containing silica sand under high pressure. This is a little bit similar to the concept behind a spray can. A sandblasting weapon, generally a two-handed design, is linked to the port on top of the cylinder by means of a specialized pipe that can withstand the abrading affects of the sand.

The Ultimate Guide To Harbor Freight Sand Blaster

Report this wiki page